Comprehensive Packaging Machine Repair Service for Quick and Effective Fixes

Comprehensive Packaging Machine Repair Service for Quick and Effective Fixes

Blog Article

Recognizing the Key Elements and Repair Work Approaches for Packaging Equipment Upkeep

Efficient maintenance of packaging equipments rests on a detailed understanding of their vital parts, consisting of the structure, drive system, and sealing systems. Recognizing usual maintenance issues, coupled with the implementation of preventative techniques and repairing techniques, can significantly boost maker integrity. Additionally, the option of repair work practices, consisting of making use of OEM parts and the value of qualified specialists, plays a crucial duty in reducing downtime. To truly comprehend the intricacies of these systems and their maintenance, one have to think about the broader effects of neglecting these necessary practices.

Trick Elements of Packaging Makers

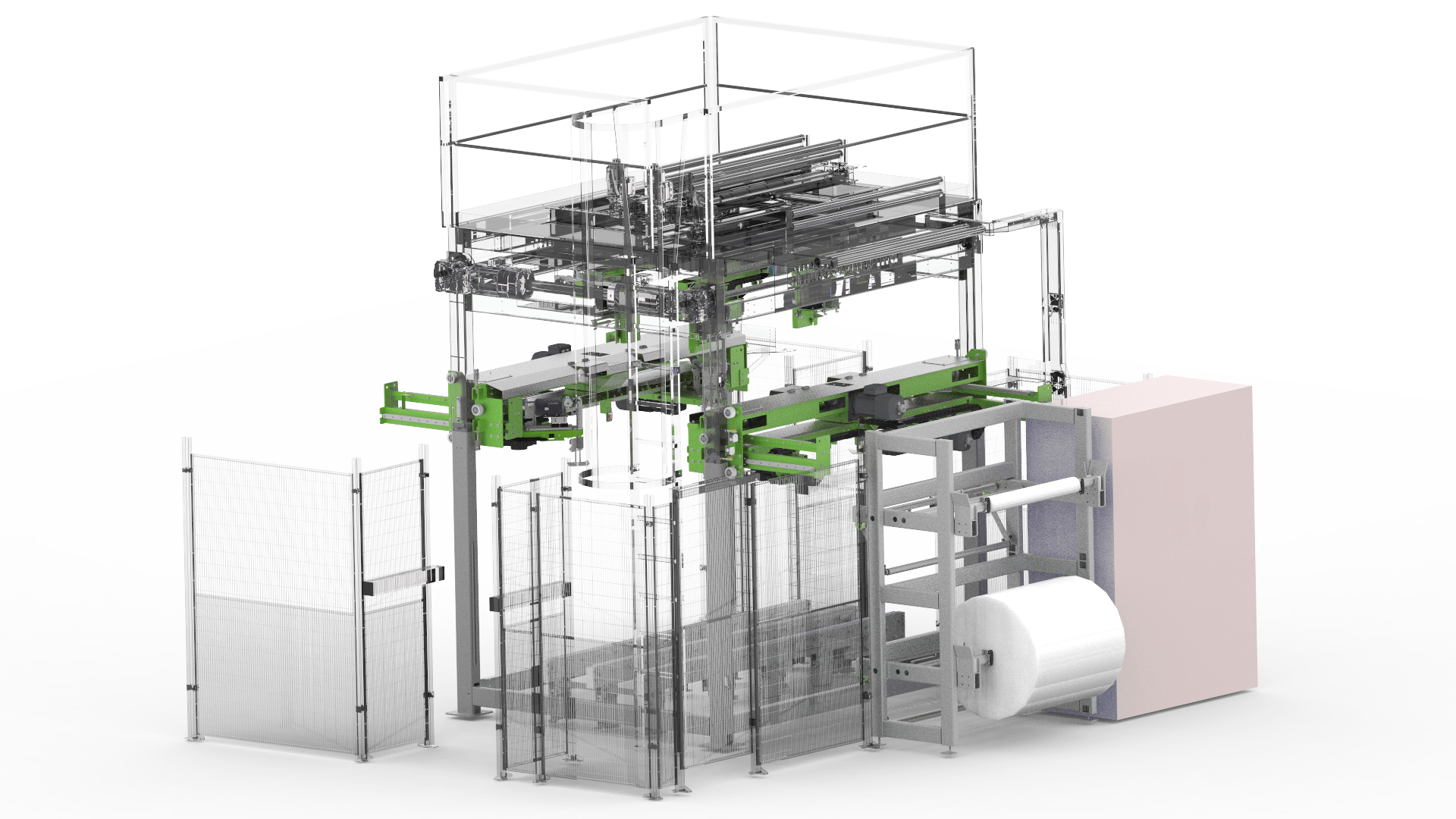

Packaging devices include a number of crucial components that function together to ensure reliable and effective product packaging processes. At the core of these machines is the framework, which supplies structural honesty and houses the different operating parts. The drive system, commonly a mix of electric motors and equipments, assists in the activity of elements, enabling exact operation throughout the packaging cycle.

One more important part is the conveyor system, which carries items via different phases of the product packaging procedure. This is usually complemented by sensing units and controls that keep an eye on the setting and rate of things, making sure synchronization and lessening errors. The loading system is crucial for properly dispensing the appropriate quantity of product right into packages, whether in liquid, powder, or strong form.

Sealing mechanisms, including warmth sealants or glue applicators, play an important role in securing packages, stopping contamination and extending service life. Additionally, labeling systems are essential for supplying essential product information, making sure compliance with policies. The control panel, furnished with user-friendly interfaces, enables operators to handle equipment functions, display efficiency, and make modifications as needed, making certain optimal productivity and performance in product packaging procedures.

Common Maintenance Issues

Reliable procedure of product packaging devices counts heavily on normal maintenance to avoid typical problems that can disrupt production. Amongst these concerns, mechanical wear and tear prevails, specifically in elements like conveyors, seals, and electric motors, which can cause unforeseen downtimes. In addition, misalignment of parts can cause inefficient operation, triggering items to be incorrectly packaged or harmed during the process.

Another typical maintenance concern entails the buildup of dust and debris, which can disrupt the machine's sensors and relocating parts. packaging machine repair service. This not just influences performance however can likewise present safety risks. In addition, lubrication failings can bring about raised rubbing, resulting in overheating and ultimate element failing.

Electrical problems, frequently originating from loose connections or worn-out wiring, can disrupt machinery functions, leading to considerable manufacturing hold-ups. Last but not least, software application glitches because of inappropriate arrangements or obsolete programs can impede the maker's operation, necessitating immediate treatment. Addressing these usual upkeep concerns proactively is important for making certain optimum efficiency and durability of packaging have a peek at this site equipment.

Preventative Maintenance Methods

Executing preventative maintenance approaches is critical for sustaining the efficiency and reliability of packaging machines. These approaches incorporate a methodical method to maintenance, concentrating on the normal examination and maintenance of tools to preempt potential failings. By sticking to browse this site an arranged maintenance program, operators can identify wear and tear on components before they lead to significant breakdowns.

Key aspects of a preventative upkeep approach include routine examinations, element, lubrication, and cleansing replacements based on maker suggestions. Utilizing lists can enhance this process, guaranteeing that no important tasks are ignored. In addition, preserving precise documents of maintenance tasks help in tracking the device's efficiency gradually, helping with notified decision-making pertaining to future maintenance needs.

Educating staff on the relevance of preventative maintenance enhances conformity and promotes a society of proactive treatment. Applying an anticipating maintenance element, utilizing information analytics and sensing unit modern technology, can further maximize equipment performance by anticipating failings before they occur.

Troubleshooting Methods

When faced with breakdowns or inadequacies in product packaging devices, using methodical troubleshooting strategies is important for recognizing and resolving concerns quickly. The first step in effective troubleshooting is to establish a clear understanding of the maker's functional specifications and efficiency metrics. This entails assessing the maker's requirements, as well as any kind of error alerts or codes displayed.

Next, operators must conduct a visual inspection, looking for apparent indications of misalignment, damage, or wear. This typically consists of checking out belts, sensing units, and gears to determine potential sources of malfunction. Collecting operational data, such as manufacturing rates and downtime logs, can also provide understandings into persisting issues.

Once potential troubles are recognized, utilizing a sensible approach to isolate the source is critical. This might require screening private elements or systems in a controlled way. Participating in discussions with drivers who connect with the machinery frequently can yield useful feedback about uncommon actions or patterns.

Repair Service and Replacement Best Practices

A thorough understanding of fixing and substitute best techniques is essential for preserving the long life and efficiency of packaging devices. Consistently evaluating the condition of machine components permits prompt intervention, preventing even more significant issues that can bring about costly downtimes.

When repair work are needed, it is necessary to use OEM (Original Equipment Producer) parts to make certain compatibility and efficiency. This not just preserves the integrity of the device however also upholds guarantee arrangements. In addition, it is recommended to maintain an inventory of crucial extra parts to help with quick replacements and decrease operational disruptions.

For intricate repair work, engaging certified you could try this out professionals with specialized training in product packaging equipment is recommended. They possess the competence to diagnose concerns precisely and implement repair work successfully. Additionally, recording all repair activities and components replacements is crucial for keeping an extensive upkeep history, which can help in future troubleshooting.

Lastly, implementing an aggressive approach, consisting of normal examinations and anticipating upkeep strategies, enhances the reliability of product packaging machines. By sticking to these best methods, organizations can make certain optimal machine efficiency, decrease functional risks, and prolong tools life-span.

Verdict

In verdict, a thorough understanding of packaging device parts and reliable upkeep strategies is important for optimum efficiency. By implementing these practices, organizations can make certain the longevity and effectiveness of product packaging equipments, ultimately contributing to improved operational efficiency and minimized prices (packaging machine repair service).

Reliable upkeep of product packaging equipments pivots on a thorough understanding of their key components, including the frame, drive system, and sealing devices.Reliable procedure of product packaging makers depends heavily on normal maintenance to avoid typical problems that can interrupt production.Implementing preventative maintenance approaches is crucial for sustaining the efficiency and integrity of product packaging devices. Furthermore, preserving accurate documents of upkeep tasks aids in tracking the equipment's performance over time, assisting in notified decision-making regarding future upkeep requirements.

Report this page